Why are there different voltages and currents?

In the next chapter I provide a more in-depth discussion of the historical origins of our electricity distribution grid; but first, let's look at the basics.

As we have already seen, the same energy can be transmitted at a lower current (and heat loss) by increasing the voltage. You might wonder why we don’t just use very high voltages everywhere.

The problem with very high voltages is that they will force high energy carrying currents to flow through even relatively poor conductors; like wet or dirty insulators; trees; or people. Even damp sea air or ionised air from lightening can be a risk. High voltage lines have also been blamed for bush-fires in Australia.

Thousands of people receive electric shocks at 240v each year without harm; but this voltage is right on the margin. Unless you can spring away you will probably be seriously injured. Annually around 150 are killed in Australia and another 1,000 hospitalised. Even 110v will kill you in the bath (popular in movies); or barefoot on a wet tiled floor.

We are partially electrical machines ourselves and excessive currents can seriously damage our nervous system; or in the extreme cook us.

The problem with lower, safer voltages is that to stop too much energy being wasted as unwanted heat; or fire; wires need to be increasingly thick and expensive.

So, to make wires carry more current without excessive heating we need either: to increase their diameter; or to use a more conductive material.

Gold and silver are very good conductors but too expensive to use except on a tiny scale in electronics.

Copper is also quite good, as is aluminium, but iron and steel; used quite extensively in hard wearing situations, like railways, are not as good.

Aluminium is widely used with many strands wrapped around a strong steel core for very high voltage lines; due to its light weight and competitive cost.

But more expensive copper can carry the same current through a thinner wire and is more corrosion resistant. There is a trade-off to decide the best option for a particular situation.

Advantages of AC

As previously mentioned, DC makes better use of a conductor and the current is uninterrupted and less heat is generated at a given current and wire diameter.

But unlike direct current (DC), alternating current (AC) in which the direction of the current reverses and then returns 50 or 60 times a second (frequency is measured in Hertz: 1 Hz = 1 cycle per second), can be used to induce an alternating magnetic field in a ‘transformer‘.

The 'mains' frequency is arbitrary from the early days. Like railway line gauges, almost any could have been chosen; within some practical limits. Europe went metric with 50 Hz; the US chose 60 Hz to synchronise with electric clocks.

A transformer enables one voltage and current combination to be converted to another with very little loss; although there is always a small additional heat penalty due to magnetic hysteresis; don't worry about this unless you are interested - Read More....

Transformers are used in their thousands all over the electricity distribution grid. These allow engineers to supply low-voltage-high-current local distribution networks with higher-voltage-lower-current power lines to minimise losses while maximising community safety.

So around your street the domestic supply lines run at 240/415volts. These local lines are supplied through transformers at regular with intervals.

You have no doubt noticed those metal covered pits in your shopping village pavement; those green humming cabinets in some streets and those grey boxes with wires going in and out up power poles. In Australia these supply the four low voltage wires (3 phases and neutral) from the local three wire intermediate voltage grid; that typically runs at 11,000 volts (and can definitely kill you).

These lines, in turn, run to an intermediate sub-station transformer supplied by a higher voltage. These substations are linked to an even larger main substation supplied by the transmission grid; running at voltages of up to half a million volts.

In low voltage distribution, most energy is lost heating the conductors (wires) and transformers but in high voltage transmission energy is also lost due to arcing (leakage) across insulators.

AC transmission is used because of the advantages transformers provide. But AC leaks some energy due to low frequency electromagnetic radiation, inducing currents in other nearby metals and other conductors that produce warming. Some cooking tops use this induction principle to heat metal pans without a heating element.

The ability to transfer energy to another circuit (or conductor) like this; by means of an induced fluctuating magnetic field is called 'induction'. The unit of inductance is the 'Henry' (H); again, named after an early researcher. The inductance of a circuit is one Henry if a current changing at the rate of one ampere per second results in a change in electromotive force one volt (H=Vs/A).

Instead of producing heat in the conductor, induction produces a varying magnetic field; that can be 'stolen' by another circuit to make a current flow. The power transferred to the 'secondary' circuit, and thus lost to the 'primary' circuit, is like another form of resistance that applies to AC; in addition to normal DC resistance.

The overall power lost or 'AC resistance' is called 'impedance'; the measure of the opposition that a circuit presents to the passage of a current when a voltage is applied. Impedance is much more difficult to calculate than simple 'resistance', as it depends on the nature of the oscillating current and voltage in an AC system; including the frequency and the 'waveform'.

In large grids impedance can cause significant losses.

Because current and voltage can get out of synchronisation (phase angle); current can be rising as voltage is falling causing additional heating in wires and transformers. The 'power factor' indicates the degree to which power is lost when the current gets out of phase with voltage and/or the waveform becomes distorted. A power factor of 1 represents no loss. If the power factor is degraded (is less than 1) a lot energy can get lost.

Over long distances all these factors can result in losses so high that the cost of energy actually transmitted becomes uneconomic.

Obviously losing 50% in transmission and distribution, before the electrical energy reaches a consumer's meter doubles the effective price of that energy to the retailer or to the wholesale market; losing 75% is catastrophic.

Some appliances like large motors or large banks of fluorescent lighting cause the power factor of the grid to become degraded. It is illegal to connect these to the electricity supply unless they have additional components to compensate/correct for this impact.

When I was a boy a popular brand of light bulb advertised on the trains that: 'Mazda Lamps use only pure electricity'. It was a joke in our family (my uncle was also an electrical engineer) that this meant they seldom worked, as the waveform and phase angle are hardly ever 'pure'. Obviously, some ignorant advertising executive was responsible for that - except that I still remember it!

But on second thoughts maybe it was 'O for an Osram'...

| The 1964 Osram Australia Campaign - There is also a link to Mazda Lamps UK Bizzare! |

Like cables that can overheat, and potentially melt, transformers can get overloaded. The amount of power a transformer can handle without getting too hot or becoming 'saturated' is specified as volts times amps or VA. For a particular frequency, in this case 50 or 60 Hz, this tends to be a function of physical size. You can quickly get an idea of the load a local grid is carrying by the size and number of transformers you can see.

Some energy is lost as electro-magnetic radiation. This almost all-pervading 50 Hz (or 60 in the US) radiation continuously bathes us throughout our lives and can be heard by touching a finger to the central (active) terminal of an amplifier or video recorder audio input.

The energy lost due to radiation rises with frequency whereas transformer size reduces, for the same VA, with frequency. This is why generators do not increase the frequency and why the older plug-packs, for charging phones, and so on, were bigger and heavier than the new ones. The old ones contained a mains frequency transformer to drop the voltage (to say 6 or 12 volts) before converting it to DC.

The newer ones multiply the frequency, so that a tiny transformer is all that is needed, before conversion to DC. They use an electronic circuit to step-up the frequency in a way that (unlike the older transformer) is relatively independent of input voltage; these are known as 'switched mode power-supplies'. The little ones (eg to recharge your phone) have an adverse impact on power factor, causing some small additional losses in the wiring in your home. The big ones, like those in your desktop PC and recent television, have power factor correction as part of their circuit.

DC transmission

In the early days of electricity transmission in the US and England a DC grid was in competition with AC.

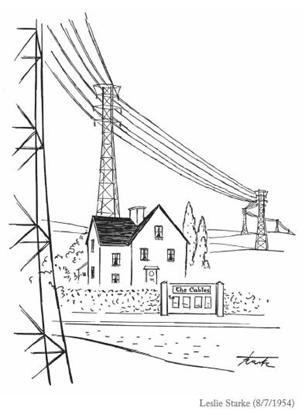

Hence the joke in the cartoon above. The initial transformer in an AC powered valve radio, used to supply high voltage to the anodes of the valves and low voltage to their filaments, would offer no impedance due to induction; just a pure resistive load with small resistive value. The 'primary' would heat very quickly and burn-out if connected to DC.

Radios were very expensive and this silly, wealthy man does not know the difference - hence the joke.

DC pulses in the grid, due to magnetic pulses from sunspots and supernova, can similarly destroy transformers in the grid; as happened in Canada in 1989.

Today the most common use of DC on a large scale is to run electric trains. All the older electric train and tram networks in Australia employ DC transmission. This was used to reduce heat losses associated with relatively low voltages and high currents.

DC was once produced directly in dedicated power-stations (like the Power House Museum in Sydney). Later it was produced by rectifying AC from the grid in substations equipped with three phase mercury-arc vapour rectifiers (like huge vacuum tubes - or light-bulbs) that glowed blue in the night and could be seen from the trains. When I was a little boy my father, who was an electrical engineer, took me to see one while it was down for maintenance; I was very impressed. Of course, I was very familiar with the old valve radios that used vacuum tube rectifiers (No 80).

DC is now produced from AC more efficiently using large silicon-based semiconductors called solid state rectifiers.

But DC has its own issues, including induced corrosion in nearby metal pipes due to the constant voltage gradient. Most modern railways, including some in Australia, now use much higher voltage AC (directly from the grid) instead.

In recent years some long distance high voltage lines have been built using DC. Read More...

Whereas an AC transformer works in both directions and a grid link can be transmitting power in one direction (say from NSW to Victoria) and then in the other virtually instantaneously; DC links, like that to Tasmania, need more elaborate conversion, to and from AC.

It's relatively easy to convert AC to DC but the reverse requires some elaborate electronics (called an inverter) to produce an alternating current in the required waveform and to synchronise it correctly to the host AC grid. Very rapid heating and equipment loss can result if this is not done properly.

If the link is to be used in both directions, rectifiers and inverters are required at both ends; with appropriate switching.

Once this could not be done economically due to heavy energy conversion losses and enormous equipment expense but in the closing decades of the last century rapid advances in ‘solid state’ silicon semiconductor technology substantially addressed these difficulties.

Although gigawatt scale equipment is still very costly, this technology can bring energy losses down sufficiently to make long distance high voltage DC transmission economically superior to very high voltage AC. This has already been so for some time, in some circumstances, particularly under salt water where AC induces electrical currents that waste energy.