The electrically literate may find this somewhat simplified article redundant; or possibly amusing. They should check out Wikipedia for any gaps in their knowledge.

But I hope this will help those for whom Wikipedia is a bit too complicated and/or detailed.

All cartoons from The New Yorker - 1925 to 2004

Think of water in a hosepipe

Electricity is a means of transporting energy from a source, like the wind, to a device you use to exploit that energy, like your electric toothbrush.

The usual way of explaining electricity is to use the simile of the flow of water in a pipe (a current of water). We are all familiar with a hose pipe. Its pressure is analogous to the voltage; and the flow of water is analogous to the current.

The author - almost two - learning about currents and voltage

The work that can be done in an hour, for example if you use the jet to spin a bicycle wheel or push leaves along a path, is the pressure (like Volts) times the current (like Amps) for an hour.

You won’t be able to squirt the water from your hose far if there is no pressure or if there is no water. You need both. If the pressure falls the water ceases to flow.

It’s the same with a stream (current) of electricity making its way down a conductor; for example, a wire. The electrical force acting on an electrical current provides the power to do work.

Most quantities in modern physics are named after an early natural philosopher or inventor. If we had let tradition do it, each would probably be related by some strange number, like the number of feet in a mile; or pounds in a ton. But most new physical values use the decimal system (the rationalised MKS or SI units: meter, kilogram, second).

A Watt is a measure of Power; the instantaneous capacity to do work; named after James Watt.

Under this system we define one Watt as equal to one Volt (electrical force) multiplied by one Ampere (current); or Amp for short. Read More...

Using this simple relationship, you can easily calculate that 1000 Watts of power (one kilowatt) can be carried by a current of 4.17 amps at 240 volts (240 x 4.17 = 1000)

But the same power requires only 0.002 amps at 500,000 volts (0.002 x 500,000 = 1000). So when you turn on an electric kettle or toaster it will draw around 4 amps in your home at 240V but only 0.002 amps in the very high voltage grid to bring it from the generator in the power station.

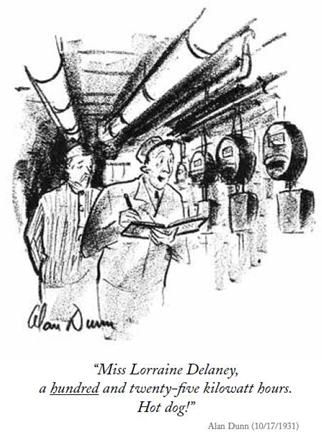

Power exerted for a period of time is called Energy. Physicists measure energy in Joules (1 J= 1Watt acting for 1 second). But to get to a smaller working number electricity companies like to measure energy in kilowatt hours (1 kWh = 3,600 kJ = a thousand Watts acting for the seconds in one hour)

When your bill comes, you get charged for the Energy, the number of kWh* you used, not Power (kW).

*Terminology: 1000 Wh = 1 kilowatt hour (kWh); 1000 kWh=1 megawatt hour (MWh); 1000 MWh = 1 gigawatt hour (GWH), 1000 GWH = 1 terawatt hour (TWh).

Hot wires

Pushing a current through a conductor requires energy. The difficulty in doing this is called resistance; and is measured in Ohms. For each Ohm of resistance an electromotive force of 1 Volt is required to cause a current of one Amp to flow. In other words Resistance = Voltage (drop across the conductor) divided by the current (Amps) in the conductor. This is called Ohms law and is obvious, a priori, from the definitions of these quantities.

The important things to know about conductors are that: resistance varies depending on the material that the conductor is made from; and the electrical energy used to overcome resistance becomes heat. Read More...

Electrical conductors get hot depending on the current flow; and the heat generated goes up exponentially as the current increases in a wire.

Suppose the lead to a power board in your kitchen is carrying 2 amps and consuming 5 Watts per metre as heat. This is so small you don’t even notice the lead getting warm. If you add a few more appliances taking the total to 10 amps the heat in the lead will jump, not to 25 watts per metre as you might expect (5x5), but all the way up to 125 watts per metre; at which point it will probably burst into flames. This is why commercial power boards have a big safety margin with wires around twice as heavy as those in this example; so there is only moderate heating even at 15 amps.

Resistance falls as conductors get fatter, in proportion to cross-sectional area. This is obvious because two identical conductors (or water pipes) side-by-side carry twice the current of one.

You may have noticed that the cord to some high current appliances, like heaters, kettles and vacuum cleaners, gets warm. To avoid heating the wires in your house too much and possibly burning it down, properly installed wiring has current ratings well above a safe limit; electricians are careful that all strands of a cable are terminated; and the current is limited by fuses and other kinds of current breakers.

We often want some wires in home appliances to get hot: electric heaters, kettles, toasters, and so on work on this principle; an incandescent light bulb generates so much heat that the filament glows white hot; a fuse wire melts if the current gets above a certain limit.

But unless you want a bit of extra warmth, heating wiring in buildings is wasteful and a fire risk. It is particularly wasteful in the street or in wires running for miles in the country. Many millions of kilowatt hours of electricity can be lost heating the countryside.

The actual losses are equivalent to approximately 10 percent of the total electricity transported between power stations and market customers. In long links and in those carrying high currents, from time to time, the losses can be much higher than this.

What is electricity - really?

Above I invited you to think of electricity as a fluid of electricity running through a conductor that acts like a pipe.

According to our present conceptual model electricity is due to the movement of electrons in a conductor. Electrons are negatively charged fermions (particles that make up an atom) that are generally happy to hang around an atom to balance the positive charge of its nucleus. Read More...

Electrons are envisaged as milling around in the general vicinity but often at a great distance, relative to the size of the nucleus, like planets around the sun. The outer electrons define the physical size of an atom. Contrary to some pictures you might have seen they do not orbit elliptically like planets but occupy a space determined by their wave function and energy state. They are happy bouncing around in this space unless something, like a photon of light or heat, encourages them to jump to another energy level.

Conductors and insulators

Some elements, like the metals, bond to each other in such a way that outer electrons can pass energy on to the next; or perhaps get shared in one big cloud.

By stimulating electrons to move we can make them carry energy along a conductor but this is more like the baton in a relay or an ‘Indian wave’ in a stadium than a flow of water. Each one in the chain just gives the next one in line a ‘shove’; pass it on. The ‘shove’ goes down the conductor and after passing-on the ‘shove’ each electron continues to hang about as before.

On the other hand, non-metals tend to form molecules in which the electrons are not free to pass energy on. A material in which no current can flow we call an insulator. Read More...

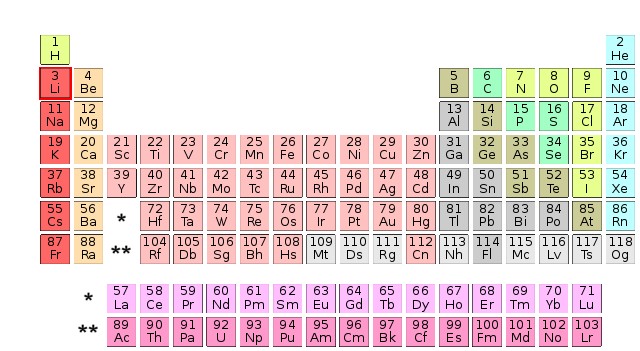

Whether an atom is a metal or not depends on the number of protons in the nucleus. After disregarding the first two (hydrogen and helium), elements can be lined up nicely by their proton count (roughly half their atomic weight) in a table: the first-row pair of 8 then 18 then 32 columns wide; so that every 8th, 18th then 32nd is similar in properties; for example: a noble gas, a halogen or an alkali.

This pattern was observed by chemists before it was explained. Once recognised it allowed chemists to see the gaps and find the missing elements. This regular pattern of repetition is called the periodic table of the elements.

Quantum mechanics now provides a model predicting/describing/explaining this observed behaviour.

Metals (the salmon-coloured elements above) are not the only conductors. Some non-metals like carbon have one form, graphite, which is a good conductor and another, diamond, which is a good insulator.

Selenium, another non-metal, has semiconducting properties and was widely used before silicone in solid state rectifiers. As a schoolboy I built several battery chargers and power supplies employing selenium rectifiers which were then easily obtained from disposals stores.

Black phosphorous is another non-metallic conductor.

If an electron is stripped from and atom (or it acquires extra electron) it is said to be ionised and if the whole atom is mobile; for example: in a fluid (gas or liquid) the whole atom can act as a transport for electrons or of positive charge (an excess of protons).

For example, salt water is a good conductor and even the earth (rocks and soil) can be used as the return conductor in a circuit.

As kids we used this in our one-wire telephone to friends in neighbouring houses.

AC and DC

When the current is in one direction only, we call it direct current DC; and when the ‘shoves’ are in one direction and then the other, back and forth like a swing, we call it alternating current or AC.

Both carry usable energy but AC makes less efficient use of the conductor as there are two points each cycle when nothing is happening and high currents, and greater loss, happens at the peaks.

So how do we make electrical currents flow?

If we want to carry energy along a conductor, we need to stimulate electrons to start passing it on as one shove to the next; in the desired direction.

By far the most common way of doing this is by passing a conductive wire through a magnetic field; or a passing a magnetic field across a wire. This gives the electrons a shove along the axis of the wire. The field has to be moving relative to the wire. A stationary field like the Earth's magnetic field requires the wire to be moving.

You have probably tried to push the matching poles of two magnets together. In the same way a magnet pushes the electrons along a wire. This push-back becomes stronger if we resist the current by putting it to use in a circuit; for example: to heat a wire or make another magnet move in a motor.

It is quite easy to make a coil of wire into an electro-magnet. This can be as strong as most magnets you might have played with.

This is how the alternator in your car makes electricity to charge the battery. It has a whole bunch of wires (usually end to end in a coil) and every turn of the shaft rotates these wires through a magnetic field. The effort required to do this is in direct relation to the energy required to charge the battery.

Most electrical generators work on this simple principle. It very efficiently turns mechanical energy into electricity; or back again to mechanical energy in an electric motor. Read More...

It's quite easy (as a child) to make one yourself and run it with a toy 'donkey engine' to light a light bulb.

3 Phase Alternator Operation (the rotating bit here can be a permanent magnet)

source: Wikipedia

Water pressure can be used to rotate the shaft of an alternator (an AC generator) below a dam.

Steam is used to drive a turbo-alternator in a coal, gas, geothermal or nuclear power-station. Petrol oil or gas engines; or wind can be used to rotate the shaft of an alternator; and tides, currents and waves drive machines to do the same thing.

There are many images of various types of power generation elsewhere on this website.

Other ways of making currents

But we can also get currents moving in other, harder to understand, ways.

A photovoltaic solar cell exploits the ability of semiconductors to allow electrons to move in one direction only. If these are then excited by energy from photons (a type of boson), they get pumped along specially designed current paths in one direction only.

This is oversimplifying a phenomenon requiring knowledge of depletion layers, electron tunnelling, and even quantum mechanics for a full explanation. You need to know a bit about semiconductors. Read More...

Photovoltaic solar cells are still in development and a lot of work is going into improving their conversion efficiency and bringing down their cost.

It is hoped that soon they will be able to provide up to 20% of our energy requirements; possibly more if we can find an economical way of storing energy from day to night and season to season.

Thermocouples employ the flow of heat in a metal from a hot area to a cold one called the Seebeck effect. Electrons in the hotter areas are more energetic than in the cooler part causing a voltage gradient. Electrons flow at different rates in different metals so if two dissimilar metals are in electrical contact near the source of heat the net difference in voltage gradient (in response to the same heat gradient) will result in a current flowing from one metal to the other.

Thus some of the heat flowing from hot to cold is converted to electricity. This is what is helping to power the recent Mars Lander: Curiosity. It uses decaying plutonium to provide the heat to thermocouples. These provide base load energy at night when Mars is very cold. Curiosity also has solar panels.

Despite maximising the differential by using very different metal alloys, the conversion efficiency of heat to electricity is still relatively poor. But efficiency is a secondary issue if the energy source is plentiful and free. The biggest issue preventing this source being used back here on earth is the equipment cost: how much energy is converted per dollar of device? Using that criterion, it's very expensive electricity indeed.

Efficiency does have an impact on physical size. This may be important is space is limited. This becomes evident when we calculate how big an area of solar panels some industries might need.

For example, an aluminium smelter would need many square kilometres of solar panels (around 30 million present generation commercial panels) to supply the electricity required to separate the metal from alumina. This would not be feasible anyway as the aluminium pots can't be shut-down overnight or on dull days.

Electricity can also be produced by ion exchange. This is the way batteries and fuel cells work.

As already mentioned, ions are negatively or positively charged atoms. These can be caused to flow by chemical and sometimes physical means.

For example, changing ion concentrations across a barrier, through which only some ions can pass (osmosis), is used very widely in nature. This happens in our body cells to produce nerve signals and; in the case of some eels, produces thousands of volts. Read More...

Why are there different voltages and currents?

In the next chapter I provide a more in-depth discussion of the historical origins of our electricity distribution grid; but first, let's look at the basics.

As we have already seen, the same energy can be transmitted at a lower current (and heat loss) by increasing the voltage. You might wonder why we don’t just use very high voltages everywhere.

The problem with very high voltages is that they will force high energy carrying currents to flow through even relatively poor conductors; like wet or dirty insulators; trees; or people. Even damp sea air or ionised air from lightening can be a risk. High voltage lines have also been blamed for bush-fires in Australia.

Thousands of people receive electric shocks at 240v each year without harm; but this voltage is right on the margin. Unless you can spring away you will probably be seriously injured. Annually around 150 are killed in Australia and another 1,000 hospitalised. Even 110v will kill you in the bath (popular in movies); or barefoot on a wet tiled floor.

We are partially electrical machines ourselves and excessive currents can seriously damage our nervous system; or in the extreme cook us.

The problem with lower, safer voltages is that to stop too much energy being wasted as unwanted heat; or fire; wires need to be increasingly thick and expensive.

So, to make wires carry more current without excessive heating we need either: to increase their diameter; or to use a more conductive material.

Gold and silver are very good conductors but too expensive to use except on a tiny scale in electronics.

Copper is also quite good, as is aluminium, but iron and steel; used quite extensively in hard wearing situations, like railways, are not as good.

Aluminium is widely used with many strands wrapped around a strong steel core for very high voltage lines; due to its light weight and competitive cost.

But more expensive copper can carry the same current through a thinner wire and is more corrosion resistant. There is a trade-off to decide the best option for a particular situation.

Advantages of AC

As previously mentioned, DC makes better use of a conductor and the current is uninterrupted and less heat is generated at a given current and wire diameter.

But unlike direct current (DC), alternating current (AC) in which the direction of the current reverses and then returns 50 or 60 times a second (frequency is measured in Hertz: 1 Hz = 1 cycle per second), can be used to induce an alternating magnetic field in a ‘transformer‘.

The 'mains' frequency is arbitrary from the early days. Like railway line gauges, almost any could have been chosen; within some practical limits. Europe went metric with 50 Hz; the US chose 60 Hz to synchronise with electric clocks.

A transformer enables one voltage and current combination to be converted to another with very little loss; although there is always a small additional heat penalty due to magnetic hysteresis; don't worry about this unless you are interested - Read More....

Transformers are used in their thousands all over the electricity distribution grid. These allow engineers to supply low-voltage-high-current local distribution networks with higher-voltage-lower-current power lines to minimise losses while maximising community safety.

So around your street the domestic supply lines run at 240/415volts. These local lines are supplied through transformers at regular with intervals.

You have no doubt noticed those metal covered pits in your shopping village pavement; those green humming cabinets in some streets and those grey boxes with wires going in and out up power poles. In Australia these supply the four low voltage wires (3 phases and neutral) from the local three wire intermediate voltage grid; that typically runs at 11,000 volts (and can definitely kill you).

These lines, in turn, run to an intermediate sub-station transformer supplied by a higher voltage. These substations are linked to an even larger main substation supplied by the transmission grid; running at voltages of up to half a million volts.

In low voltage distribution, most energy is lost heating the conductors (wires) and transformers but in high voltage transmission energy is also lost due to arcing (leakage) across insulators.

AC transmission is used because of the advantages transformers provide. But AC leaks some energy due to low frequency electromagnetic radiation, inducing currents in other nearby metals and other conductors that produce warming. Some cooking tops use this induction principle to heat metal pans without a heating element.

The ability to transfer energy to another circuit (or conductor) like this; by means of an induced fluctuating magnetic field is called 'induction'. The unit of inductance is the 'Henry' (H); again, named after an early researcher. The inductance of a circuit is one Henry if a current changing at the rate of one ampere per second results in a change in electromotive force one volt (H=Vs/A).

Instead of producing heat in the conductor, induction produces a varying magnetic field; that can be 'stolen' by another circuit to make a current flow. The power transferred to the 'secondary' circuit, and thus lost to the 'primary' circuit, is like another form of resistance that applies to AC; in addition to normal DC resistance.

The overall power lost or 'AC resistance' is called 'impedance'; the measure of the opposition that a circuit presents to the passage of a current when a voltage is applied. Impedance is much more difficult to calculate than simple 'resistance', as it depends on the nature of the oscillating current and voltage in an AC system; including the frequency and the 'waveform'.

In large grids impedance can cause significant losses.

Because current and voltage can get out of synchronisation (phase angle); current can be rising as voltage is falling causing additional heating in wires and transformers. The 'power factor' indicates the degree to which power is lost when the current gets out of phase with voltage and/or the waveform becomes distorted. A power factor of 1 represents no loss. If the power factor is degraded (is less than 1) a lot energy can get lost.

Over long distances all these factors can result in losses so high that the cost of energy actually transmitted becomes uneconomic.

Obviously losing 50% in transmission and distribution, before the electrical energy reaches a consumer's meter doubles the effective price of that energy to the retailer or to the wholesale market; losing 75% is catastrophic.

Some appliances like large motors or large banks of fluorescent lighting cause the power factor of the grid to become degraded. It is illegal to connect these to the electricity supply unless they have additional components to compensate/correct for this impact.

When I was a boy a popular brand of light bulb advertised on the trains that: 'Mazda Lamps use only pure electricity'. It was a joke in our family (my uncle was also an electrical engineer) that this meant they seldom worked, as the waveform and phase angle are hardly ever 'pure'. Obviously, some ignorant advertising executive was responsible for that - except that I still remember it!

But on second thoughts maybe it was 'O for an Osram'...

| The 1964 Osram Australia Campaign - There is also a link to Mazda Lamps UK Bizzare! |

Like cables that can overheat, and potentially melt, transformers can get overloaded. The amount of power a transformer can handle without getting too hot or becoming 'saturated' is specified as volts times amps or VA. For a particular frequency, in this case 50 or 60 Hz, this tends to be a function of physical size. You can quickly get an idea of the load a local grid is carrying by the size and number of transformers you can see.

Some energy is lost as electro-magnetic radiation. This almost all-pervading 50 Hz (or 60 in the US) radiation continuously bathes us throughout our lives and can be heard by touching a finger to the central (active) terminal of an amplifier or video recorder audio input.

The energy lost due to radiation rises with frequency whereas transformer size reduces, for the same VA, with frequency. This is why generators do not increase the frequency and why the older plug-packs, for charging phones, and so on, were bigger and heavier than the new ones. The old ones contained a mains frequency transformer to drop the voltage (to say 6 or 12 volts) before converting it to DC.

The newer ones multiply the frequency, so that a tiny transformer is all that is needed, before conversion to DC. They use an electronic circuit to step-up the frequency in a way that (unlike the older transformer) is relatively independent of input voltage; these are known as 'switched mode power-supplies'. The little ones (eg to recharge your phone) have an adverse impact on power factor, causing some small additional losses in the wiring in your home. The big ones, like those in your desktop PC and recent television, have power factor correction as part of their circuit.

DC transmission

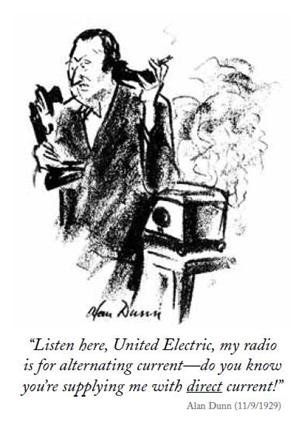

In the early days of electricity transmission in the US and England a DC grid was in competition with AC.

Hence the joke in the cartoon above. The initial transformer in an AC powered valve radio, used to supply high voltage to the anodes of the valves and low voltage to their filaments, would offer no impedance due to induction; just a pure resistive load with small resistive value. The 'primary' would heat very quickly and burn-out if connected to DC.

Radios were very expensive and this silly, wealthy man does not know the difference - hence the joke.

DC pulses in the grid, due to magnetic pulses from sunspots and supernova, can similarly destroy transformers in the grid; as happened in Canada in 1989.

Today the most common use of DC on a large scale is to run electric trains. All the older electric train and tram networks in Australia employ DC transmission. This was used to reduce heat losses associated with relatively low voltages and high currents.

DC was once produced directly in dedicated power-stations (like the Power House Museum in Sydney). Later it was produced by rectifying AC from the grid in substations equipped with three phase mercury-arc vapour rectifiers (like huge vacuum tubes - or light-bulbs) that glowed blue in the night and could be seen from the trains. When I was a little boy my father, who was an electrical engineer, took me to see one while it was down for maintenance; I was very impressed. Of course, I was very familiar with the old valve radios that used vacuum tube rectifiers (No 80).

DC is now produced from AC more efficiently using large silicon-based semiconductors called solid state rectifiers.

But DC has its own issues, including induced corrosion in nearby metal pipes due to the constant voltage gradient. Most modern railways, including some in Australia, now use much higher voltage AC (directly from the grid) instead.

In recent years some long distance high voltage lines have been built using DC. Read More...

Whereas an AC transformer works in both directions and a grid link can be transmitting power in one direction (say from NSW to Victoria) and then in the other virtually instantaneously; DC links, like that to Tasmania, need more elaborate conversion, to and from AC.

It's relatively easy to convert AC to DC but the reverse requires some elaborate electronics (called an inverter) to produce an alternating current in the required waveform and to synchronise it correctly to the host AC grid. Very rapid heating and equipment loss can result if this is not done properly.

If the link is to be used in both directions, rectifiers and inverters are required at both ends; with appropriate switching.

Once this could not be done economically due to heavy energy conversion losses and enormous equipment expense but in the closing decades of the last century rapid advances in ‘solid state’ silicon semiconductor technology substantially addressed these difficulties.

Although gigawatt scale equipment is still very costly, this technology can bring energy losses down sufficiently to make long distance high voltage DC transmission economically superior to very high voltage AC. This has already been so for some time, in some circumstances, particularly under salt water where AC induces electrical currents that waste energy.

The Electricity Grid

Before electricity there was gas to provide heating and lighting. This was predominantly producer-gas, a mixture of carbon-monoxide and hydrogen, reticulated through pipes from a gasworks. And so, with the advent of the dynamo, early electricity grids were similarly represented, to the degree that people often turned-off switches to prevent the electricity leaking into their homes.

Now most people know that electricity is fundamentally different. Whereas gas is a fuel in itself, electricity is nothing but an energy transmission medium. In addition, it requires a completed 'circuit' to flow. Albeit, that this could incorporate you, as a component.

The Current Wars of the 1880's

In the United States, Thomas Edison, wanted to commercialise his electric light bulb as a competitor to gas lighting. So, initially, the Edison Electric Light Company used coal-fired steam engines to spin German dynamos, to provide low voltage (110V) DC electricity to supply his incandescent lighting customers. This required many small local power stations (deriving their energy from fossil fuels), as the low voltage and resulting high currents heated the distribution cables, losing energy, and limiting the practical range to a few tens of miles.

His local competitor, George Westinghouse, would acquire the US right to European (British/Italian) technology that overcame the distance problem, using AC at relatively high voltages (3,000 to 5,000VAC) limiting the current (see above) and extending the range. These voltages facilitated electric arc lighting, used in large public spaces, but which was unsuitable for domestic use.

In the, now familiar manner, transformers, also invented in Europe, were used to step-down the voltage and the step-up current near the consumer. These brought Westinghouse into direct competition with Edison. A brilliant engineer, employed by Westinghouse, would improve transformer design, such that (for small single-phase transformers) it has hardly changed ever since. Although, switch mode (electronic) power supplies have replaced many small transformers in the past four decades.

Edison claimed that this high voltage AC distribution was extremely dangerous and electrocuted a number of animals to demonstrate his point. It was indeed dangerous, as the high-voltage lines were mounted on the same poles as the telegraph. A telegraph lineman, John Freeks, was soon electrocuted, forcing the high voltage lines underground.

But unfortunately, Edison's design for an electric chair overestimated how instantaneously deadly Westinghouse's few thousand volts could be. It virtually burnt the man to death.

My father told the story of the notoriously bad-tempered man who collected the fares on a New York streetcar.

| One day, the ticket-collector lost his temper, yet again, he'd been warned several times, and angrily threw and old lady under the wheels of a passing horse-drawn cart. He was sentenced to the electric chair for murder. But after the third attempt to electrocute him, he remained unharmed. So, under the US Constitutional prohibition against 'cruel and unusual punishment', the Governor was obliged to grant him a pardon, conditional upon his attendance at an anger management seminar. An outraged reporter asked him if he had employed some trick, as he had requested specially imported red bananas for his last meal. "Was it those expensive bananas in your foul gut that saved you, you damn nanny-killer?" the reporter demanded to know. "No," came the man's calm reply (the seminar had worked), "I'm just a very bad conductor." |

But in the end, AC was here to stay. The Current Wars ended when Edison lost full control and his company, General Electric, became one of the world's great manufacturers of turbo-alternators and high voltage (AC) grid equipment. Seventy years later a subsidiary, Australian General Electric, would employ my father and put a roof over our heads.

In Europe a similar process was underway, advanced by the invention of arc lighting by Sir Humphrey Davy and the incandescent lamp by Swan (Edison's partner), first demonstrated in Newcastle in England; the modern transformer in Budapest; and the invention of three-phase long distance transmission grid in Germany.

I add these because many Americans and therefore Australians, seem to believe that electricity transmission and electric lighting were exclusively invented in North America. Yet it's true that the great American entrepreneurs certainly knew how to develop and commercialise an idea. See: The History of Alternating Current (an American perspective).

So, in Australia, we have a hybrid and our electrical engineers like to think it's the best of both worlds. For example, our very functional 240VAC domestic plug is actually an American design, well in advance of the various British equivalents, that has served us well for around a century.

During that time electricity became our predominant source of domestic; industrial; commercial; and increasingly, transport; energy and the electricity grid grew to become one of the largest in the world. Yet as a result of high levels of urbanisation, separated by vast distances, electricity distribution in Australia faces some unique challenges. See the Appendix: The National Electricity Market (NEM) for more details.

Like the managers of electricity grids worldwide, the Australian Energy Market Operator (AEMO), that manages the eastern Australian grid, has the task of matching supply to demand.

Electricity demand is extremely volatile. It varies greatly during a single day from hour to hour; it differs from day to day during a week; it differs from season to season; it's affected by the temperature and the weather; even by sporting matches other events; and what's on television. At one time most of this was quite predictable, so sufficient generators could be on standby or safely taken off-line for maintenance.

Yet a small but increasing number of solar and wind generators are unpredictable, at the whim of nature, so there needs to be a means of meeting demand peaks when it is dark and there is no wind and, conversely, when there is plenty of wind and the sunny skies are clear but little demand.

As a result of the NEM, when demand is low, and a lot of generators, particularly wind and solar are feeding the grid, the wholesale price of electricity can go negative.

On the other hand, when generation falls short of demand, the price per MWh can go very high indeed.

With a preponderance of wind energy, the spot price in South Australia often reached the $15,000 maximum this year, sometimes several times a day, while at other times the price went negative so that generators had to pay to dispose of excessive electricity.

These fluctuations provide a strong market incentive for storage providers, for example battery owners or pump-hydro facilities, to buy electricity at very low prices and sell it back at very high prices.

Therein the difficulty lies, storing electricity on a large scale, without significantly increasing its cost, is problematic.

Approaches to Electricity Storage

Storage Batteries (accumulators)

We are all familiar with batteries (accumulators). There have been huge advances in battery technology in my lifetime that have made electricity storage on a megawatt-hour (MWh) scale practical.

Accumulators, also called 'secondary cells', store electricity by converting it to chemical energy employing a reversible chemical reaction that enables them to be charged and discharged repeatedly.

Although small batteries (D; AA and AAA cells for example) are often packaged alike, to facilitate interchangeably, accumulators should not be confused with one-use 'primary cells', that employ an irreversible electrochemical reaction that consumes or depletes the chemicals employed.

In addition to high energy efficiency (very low charge and/or discharge losses) an ideal storage battery would be constructed from plentiful; non-toxic chemicals; and would be light weight to enable its use in vehicles and hand-held devices. It would work in any climate and safely store chemical energy at a higher density than any other storage.

Obviously, the chemical reaction employed must be reversible and be stable over time. Cycling should be possible many thousands of times over, before the storage qualities are significantly degraded. And recharging should be as fast as possible.

For more than a century our best rechargeable battery was the lead-acid accumulator, like that used to start a conventional car; truck; or bus.

Then, in the last decade of the 20th century, new materials based on rare-earths offered new avenues of research. Commercial nickel metal-hydride (NiMH) batteries, became a reality. Nickel is less dense than lead and the new batteries packed twice as much energy per kilogram as lead-acid cells. As an added bonus they could be small or large and had no messy liquid acid or fumes. This improvement opened the way to many new types of hand tools and electric vehicles.

For many years lithium shimmered as the 'Holy Grail' of battery technology. Lithium is the lightest metal and the least dense solid element. It's also highly reactive, with the greatest electrochemical potential and energy-to-weight ratio of any element in the periodic table.

But lithium metal is so reactive that it spontaneously bursts into flame and early attempts to build a safe and practical battery ended in tears. Nevertheless, work went on, involving many improvements until, in 1985, Akira Yoshino assembled the first practical rechargeable lithium-ion battery at the Kawasaki Laboratory of the Asahi Kasei Corp in Japan. His new battery avoided using lithium metal directly, making it less unstable, yet provided another doubling in energy density over NiMH.

With volume, the battery prices quickly fell, so that new opportunities and markets, like little drones and more complex telephones, proliferated. The trouble is that Li-ion batteries are still rather dangerous. Higher current energy density comes with a risk, as Boeing discovered on their new 787; as did UPS when a battery fire brought one of their planes down. Samsung too had to withdraw their Samsung Galaxy Note 7 due to higher density batteries catching fire.

Further increase in chemical energy density is likely to make accumulators even more dangerous, equivalent to a high explosive, like TNT.

The electric car maker Tesla is well aware of the dangers inherent in the lithium-ion (Li-ion) batteries it uses. At the moment the Tesla battery has about the same energy as 75 kg of TNT. To obviate the risk of a single explosion the Tesla 'battery' is not a single unit but consists of over seven thousand individual Li-ion cells, similar to the familiar 'D' cell, packed into 16 separate modules, that are distributed across a wide pan below the car.

Despite the well-published failures, an attractive feature of Li-ion technology, compared to other very high energy batteries, is its relative safety. So, most of us walk around happily with a small one in our mobile phone.

Some advocates of all-electric cars promote them as grid storage. But this is problematic as they could also have the effect of contributing to the demand- supply mismatch. Cars are mostly driven during the day, at morning and evening peak-hour, and charged in the middle of the day and at night. Daytime charging may match peak solar but drivers do not stop to charge when the wind is blowing or avoid charging when it is dark and there is no wind.

Stationary batteries are designed to do just this and are a much better option than those being driven about. Thus, many homes with rooftop solar panels, now also have a storage battery to smooth the peaks and troughs in the electricity generated as the solar incidence on their panels varies, often minute to minute; hour to hour. And on a grid supply scale, South Australia, that is saturated with variable wind energy, has installed several mega-batteries, to cope with mismatched demand and supply peaks.

Continuing improvement in batteries can be expected and there are other options beyond lithium for stationary batteries, where energy density is less important that overall efficiency (minimal energy lost during a cycle) and capital cost (per MWh stored).

Here are some features of present generation of, advanced, high-energy-density, batteries:

| Nickel metal-hydride (NiMH) Energy density Specific power Charge/discharge efficiency Self-discharge rate Low self-discharge types: Cycle durability |

140–300 Wh/L 250–1,000 W/kg 66%-92% 13.9–70.6% (per month) 1.3–2.9% (per month) at 20 °C 180–2000 cycles |

Lithium-ion Energy density Specific power Charge/discharge efficiency Self-discharge rate Cycle durability |

250–676 Wh/L ~250-~340 W/kg 80–90% 8% (per month) at 21 °C 400–1200 cycles |

Source: Wikipedia: NiMH - Lithium-ion

Hydrogen

That electricity can be used to disassociate water, into hydrogen and oxygen, was one of the fist observations arising out of the discovery of electrical currents at the turn of the 18th century. Electrolysis was described, and named, by Michael Faraday, at that time Sir Humphry Davy's research assistant responsible for demonstrations of scientific discoveries to the educated classes in England. Later Faraday would make ground-breaking discoveries himself including his 'first and second laws of electrolysis' in 1833. Both the Faraday Cage, that protects high-voltage workers from death, and the Farad, the unit of electrical capacitance, are named after him.

As a result, hydrogen was soon seen to be a possible means of capturing electrical energy. As home and then in High School physics we did it for ourselves.

For example, in 1874 Jules Verne had a similar vision but misunderstood electricity. Believing it to be like gas, a source of the energy in itself:

The Mysterious IslandJules Verne 1874 “Yes, but water decomposed into its primitive elements,” replied Cyrus Harding, “and decomposed doubtless, by electricity, which will then have become a powerful and manageable force, for all great discoveries, by some inexplicable laws, appear to agree and become complete at the same time. Yes, my friends, I believe that water will one day be employed as fuel, that hydrogen and oxygen which constitute it, used singly or together, will furnish an inexhaustible source of heat and light, of an intensity of which coal is not capable. Some day the coalrooms of steamers and the tenders of locomotives will, instead of coal, be stored with these two condensed gases, which will burn in the furnaces with enormous calorific power. There is, therefore, nothing to fear. As long as the earth is inhabited it will supply the wants of its inhabitants, and there will be no want of either light or heat as long as the productions of the vegetable, mineral or animal kingdoms do not fail us. I believe, then, that when the deposits of coal are exhausted we shall heat and warm ourselves with water. Water will be the coal of the future.” |

Then in 1923, scientist and polymath, J B S Haldane, rectified this rather serious shortcoming: an inexhaustible source of heat and light; by proposing a network of electricity-generating windmills to produce hydrogen for distribution in Britain.

Hydrogen was, by then, already being piped around British and Australian cities (also British at the time) from gasworks, that manufactured producer gas (a mixture of hydrogen and carbon monoxide) from coal and steam. And the house in which I'm writing this was once lit by gas; heated by gas (still is); cooking was by gas (some still is) and the hot water was by gas (ditto). So, when I go to the side of the house, I still see a slope, and drop pipes below upward pipes, on the original gas plumbing. These were designed to capture entrained water vapour that condensed out. So, occasionally, if the gas petered-out, the plug at the bottom of the run would be removed to drain water from the system.

Yet these are no longer necessary, the gas no longer contains water vapour (or free hydrogen) - the gasworks are all gone to be superseded by natural gas - mostly methane.

So, given that hydrogen, from electrolysis, has been fêted for so long, why hasn't it happened yet?

There are several reasons:

Cost, handling, safety and competitiveness; when used as a transport fuel:

Hydrogen is a lot cheaper to make in the old way, than by electrolysis. Commercial hydrogen is made by applying steam and extra heat to a hydrocarbon like petroleum; or natural gas; or coal. This generates a lot of carbon dioxide as a by-product (and wastes energy, compared to burning the hydrocarbon or coal directly).

Yet, even this relatively inexpensive, anything but green, hydrogen, has not taken off as a transport fuel.

This is partly due to distribution and storage issues, compounded by some unique safety concerns.

Although hydrogen is very light and liquid hydrogen has three times the energy per kg of LPG (it's good as a rocked fuel) it takes around three litres of liquid hydrogen to provide the same energy as a litre of LPG. And with a boiling point of −252.9 °C (−423.2 °F) it's much harder to compress and store than LPG (-42°C or -44°F) that is easily compressed and transported as liquid at normal temperatures.

To be used as a transport fuel, hydrogen must either be compressed, or converted to a metal hydride.

Compressed to 50 atmospheres pressure, as used in cars and buses, hydrogen has less than a 50th of the energy per litre than petroleum or natural gas. This requires much larger and more expensive tanks and dramatically reduces the practical range, compared to LPG powered vehicles.

So, why destroy a perfectly good transport fuel like LPG; or natural gas; or even coal; to make an inferior one?

And when it comes to hydrogen fuelled (using a fuel cell) electric vehicles: why not simply use the electricity directly?

Energy efficiency:

To be useful, as an electricity storage means, very little of the energy should be lost in recovering the electricity. Yet hydrogen is very poor in this regard.

Conventional electrolysis just electrodes in water, as we did as kids, is very inefficient, wasting up to half of the electrical energy, but new polymer electrolyte membrane (PEM) electrolysis is much more efficient, at around 85% and possibly higher (15% lost to start with). But that's just half the story.

To get the electricity back there are two approaches: the hydrogen can be used to power a heat engine, to spin a dynamo or alternator, or the hydrogen can be reacted with oxygen in a fuel cell, recovering the water destroyed during electrolysis.

The former is very wasteful, as heat engines lose up to 70% of the energy expended.

Hydrogen fuel cells are more efficient but still convert 60% to 70% of the energy to heat (rather than electricity).

This is fine if you can use the heat, for example: to heat domestic or industrial water, but a terrible way to recover the electricity originally invested.

If we assume 15% of the energy is lost during electrolysis and at least 40% is lost converting the hydrogen back to electricity, then the best equivalent charge/discharge efficiency we could expect would be 35%. This compares to a lithium-ion battery that achieves 80–90% (see above). Further, the equipment involved is far more complex and costly than an equivalent modern battery.

Hydrogen as a transmission medium:

Some have suggested, like Haldane in 1923, that electrolysis could be an option for solar or wind power stations in remote locations, like Central Australia. The hydrogen would be then be piped to where the electricity is needed. But this raises several more issues. Pipelines require pumping stations and these require energy, usually drawn from the gas or liquid being piped. The overall losses, together with capital servicing costs, would need to be less than possible alternatives like: very high voltage DC transmission; or even batteries on a train (boat; trucks; - you name it).

Yet there is a scenario in which electrolysis of water makes sense; and it goes back to J B S Haldane. If electrically-disassociated-hydrogen, from wind; or PV solar generators; was added to existing gas distribution networks, as Haldane envisaged, it would transmit the energy to down-stream gas users and lower the overall release of carbon, when the gas is burnt.

This would require significant volumes of water (making hydrogen from water obviously requires water). And around the same volume of water destroyed at the source is recreated at the end. This would limit the practicality in some locations, like arid Central Australia, but coastal windfarms suggest themselves. And some larger energy markets, that already have desalination plants, might benefit from some additional water.

But as a storage method for electricity, hydrogen is a non-starter - wasteful of energy and uncompetitive with several other options.

Again, a paper, that is much more erudite than mine, convincingly confirms that converting electricity to hydrogen and then back to electricity in vehicles makes no sense. Batteries do it a great deal more efficiently. Click here to read Professor Bossel's analysis...

The same applies to other applications, like load-shedding, as there are several other methods of storing electricity that are vastly superior to employing hydrogen.

Pumped-Storage Hydropower (PSH)

The Australian Federal Government is pinning its hopes on pumped-storage.

Until recently the only commercial large scale (terawatt) method for storing energy was pumped-storage, associated with hydroelectric schemes. The best of these loses 20 to 30% of the energy in pumping water up hill and then letting it run back through the turbines. While the energy efficiency is less than the latest batteries, in the long term, pumped-storage may be more cost-effective.

Pumped storage is primarily used for providing extra generation when consumer demand is high; or pumping when there is a long spell of excessive generation form wind or solar; not for absorbing wildly fluctuating generation from wind or solar farms, where batteries are now proving effective.

In Australia present hydro-generation is far too small and unresponsive to compliment a large-scale contribution of solar energy. In 2021 the capacity of the Snowy Mountains Hydroelectric Scheme is only 7.8GW. Present pumped storage capability is presently 0.6 GW, a tiny fraction of this. This will be expanded with the addition of 27km of tunnels and building a new underground power station, by a further 2 GW, when the present Snowy 2.0 project is completed in 2026.

To put this into context, total installed electricity capacity in the National Electricity Market (NEM) in 2021 is 52.5 GW. So, after completion, Snowy 2.0 will contribute less than 5%. This is significant at present but not if the mix of highly variable renewable rises to become a larger part of the generation mix. By comparison the installed capacity of Eraring, just one of of five coal-fired power-stations in New South Wales, is 2.8 GW.

Back in the day, when Josh Frydenberg (now Treasurer) was Federal Energy Minister, he proposed a pumped hydro storage facility at Cultana on the Eyre Peninsula that could protect South Australia from power shortages that lead to load-shedding blackouts. And announced that work is underway to make such a facility a reality.

"The Cultana defence site has pipelines, transmission lines and roads connected to it... It might only take a couple of years to complete," he assured South Australians.

He went on to point out that: "97% of {world} energy storage was in pumped hydro. "It’s been underdone in Australia,” he said: “We have now tasked the Australian Renewable Energy Agency and the Clean Energy Finance Corporation in a new funding round for large-scale storage, including pumped hydro.”

ANU Professor Andrew Blakers (Engineering) supported the Minister's proposal.

"The possibilities are almost unlimited," Prof Blakers is reported as telling the Adelaide Advertiser (or was it a press release?): "because you can build as many facilities as you like... We’re looking for a decent volume, and a big height differential from the upper to the lower. Ideally 400 to 500 metres," the good Prof enthused.

"It would be largely trouble free, using well proven hydro generation technology, and last for in excess of 50 years, as opposed to batteries which, very optimistically, even if improved, would last for a tenth of that time."

"You would look typically at 300 MW and a 10-hectare reservoir... If you want more, you just make more - four or five or six.”

"This form of hydro doesn’t need a river. It works by pumping water from a lower reservoir to a higher one when energy is cheap, then letting the water run down again through a turbine when it’s expensive... A standard model would cost up to $500 million, but would last 50 years and be able to generate 300 megawatts."

Meanwhile, Josh reminded us, that he and the Prime Minister had already announced a $2 billion expansion of the Snowy Mountains hydro scheme to address energy security: "...preventing power shortages in eastern states... The first major expansion of Snowy Hydro scheme since construction completed in 1974."

In the event, in 2018 the Cultana Pumped Hydro Energy Storage Project proceeded to a detailed engineering and financial pre-feasibility analysis (Phase 2 of the project). This found environmental; unforeseen capital cost; and competition (from alternative solutions) issues that rendered this project non-viable.

You can read the Energy Australia & Arup report Here...

Section: 6.2.2 Higher Renewables Penetration, makes interesting reading, as does the analysis of the initial proposal to pump seawater. This turns out to be non-viable in this location for environmental and engineering reasons.

It also turns out that, in addition to the obvious competition from batteries, the interlinks to Victoria and now New South Wales (Read More...) are significant competitors and that the very long life-expectancy of pump-storage makes it less attractive to commercial investors. Batteries are actually more attractive because of their predictably shorter life-expectancy.

And if we use Prof Andrew Blakers numbers, pumped hydro would have an upfront cost of three to five times that of batteries.

Maybe the price equation has changed but again, the Snowy, even with a modest expansion, is far too small to secure energy security if we persist in a reliance on wind energy and solar alone to replace existing coal fired electricity generation. As the above report makes clear, thermal energy will still be required as part of any practical mix. Carbon-based or nuclear?

South Australia is a small part of the National Electricity Market (5.8% of the NEM) and this project might have made a contribution but we would need several Snowy Schemes to do the same for the larger states. Good luck with the Greens on that one.

Other Mechanical

Pumping water uphill can be viewed as mechanical energy storage. Storing potential energy, as the grandchildren do with the cuckoo-clock in the kitchen, hauling up the pinecone shaped weights to watch them fall while driving the mechanism and, of course, the music box, winding the spring.

It's somewhat ironic that when electric trams replaced cable cars the energy efficiency equation worked the other way. Why convert mechanical energy to electricity and back to mechanical energy when one can use the mechanical energy directly, the cable car companies demanded to know. The same argument applied to factories in which mechanical energy was delivered directly to machines by belts from overhead shafts.

But this is where electricity shines.

Flywheels are a good example of mechanical storage. Motors store energy into flywheels by accelerating their spins to very high rates (up to 50,000 rpm). The motor can later use that stored kinetic energy to generate electricity by going into reverse. Flywheels are commonly left in a vacuum so as to minimize air friction, which would slow the wheel.

The Stephentown Spindle in Stephentown, New York, unveiled in 2011 with a capacity of 20 MW, was the first commercial use of flywheel technology to regulate the grid in the United States. Several other flywheel facilities have since come on line.

Flywheels are not suitable for long-term energy storage, but are very effective for load-levelling and load-shifting applications. Flywheels are known for their long-life cycle, high-energy density, low maintenance costs, and quick response speeds. Over short peaks the latest flywheels have similar energy efficiency to batteries.

Compressed air has also been used overseas (in the US and Germany) as an energy complement to a gas turbine electricity generator. The air is pumped into a cavern when electricity is cheap and boosts the energy of a gas turbine during peak load.

My brother is an advocate of mechanically lifting weights. Others suggest pressurising gas to drive water through a turbine, for example in underwater bags. But in each case, capital cost and conversion efficiency remain significant hurdles.

Heat

Heat has been the principal source of electrical energy for over a century. This has been principally derived from burning fossil fuels but geothermal heat, solar heat, and heat from nuclear fission have also played a significant part in various parts of the world.

As mentioned elsewhere, converting heat to electrical energy is most efficiently done on a small scale using thermo couples. Mechanically, the most efficient conversion is by Sterling Engine. But combining cost and efficiency, using steam or hot gas to spin turbines, and thus alternators, is almost always used in thermal power stations. Energy efficiencies of up to 47% are possible using ultra-critical technology.

In a power station in Spain heat from solar collectors is stored in molten salt that in turn heats water but the efficiency of relatively low temperature steam is well below ultra-critical.

So it makes little sense to store electricity and heat, unless there is another use for low-grade heat, for example water or greenhouse heating, as considerably less than half the energy will be recoverable as electricity.

There is a discussion of the Spanish experience using hot salt for storage, in the article on Spain.

Other electro-chemical conversion possibilities

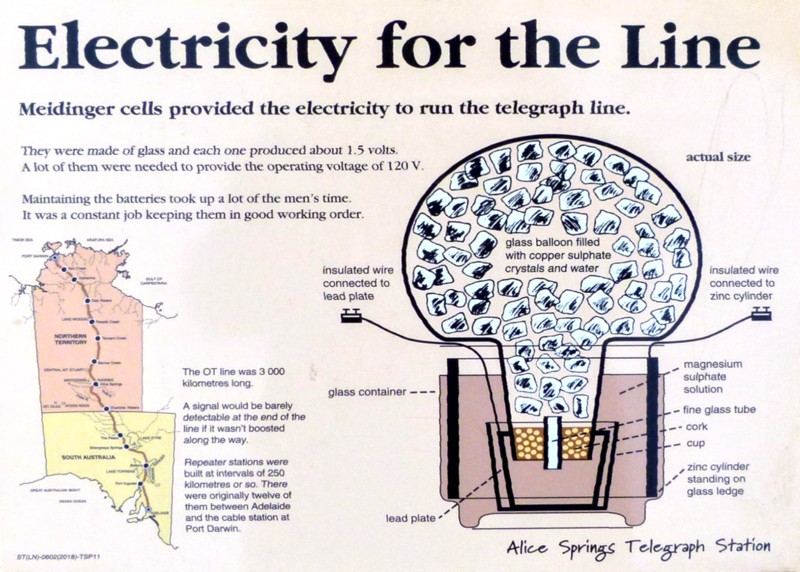

In June 2021, Wendy and I, with our friends Craig and Sonia visited Alice Springs in Central Australia and while there went to see the historic Overland Telegraph (repeater) Station where telegraph messages were weakly received and re-keyed with renewed energy. But where did the energy come from?

It was from batteries of course but they had no way to charge these batteries and they were primary cells, that consumed the chemicals that combined to release their electricity. Tons of chemicals were shipped in by camel and tending the batteries was a principal responsibility of the Station staff taking up much of their time.

The electrical energy that was thus released was chemical energy that had been imparted to the copper-sulphate magnesium-sulphate and zinc metal in furnaces, in factories back in the industrial world, primarily by burning coal.

Similarly, the zinc-carbon or alkaline primary cells in your TV remote consume chemicals created by smelting, often using electricity to impart that energy.

Thus, today, aluminium is sometimes described as frozen electricity. But just like hydrogen far more energy is imparted than can be recovered as electricity.

Nevertheless, the hunt is still on for more efficient electrochemical processes that could supplant conventional batteries.

The Future

Transmission

As electricity prices rise there is pressure to make our current systems more efficient.

Some commentators have suggested converting the whole grid to direct current, DC. This would decrease grid losses and extend the grid's practical geographic reach.

As it turns out my family was once heavily invested in DC systems (see The McKie Family - Untimely Death), leading to events without which I would not have been born.

As advocates point out most of today's electronic devices could easily be converted to run on DC. But most current generation motorised appliances could not and would require an inverter.

All the transmission and distribution transformers, of which there are hundreds of thousands, would need to be replaced by much more complex electronic equivalents that, nevertheless, may be less costly; when mass produced.

Although the conversion would be daunting it would be a way of saving some of the energy presently lost to simply heating the environment.

It would also reduce or eliminate the constant low frequency radiation that now surrounds us: the buzzing noise you hear if you touch your finger to an open microphone connection.

This could be a dubious benefit as there is no evidence that this radiation is harmful. It is even possible that this actually protecting us from more dangerous natural radiation; and is a factor in people living longer today than in the past.

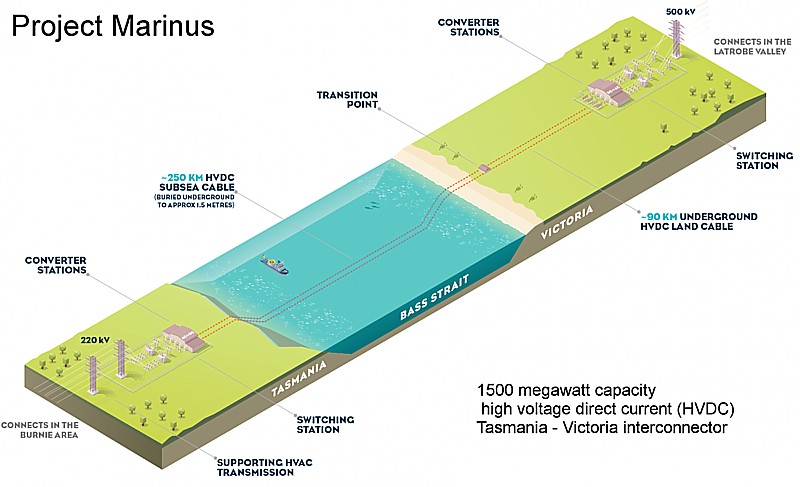

In the meantime the use of DC links within the Eastern Australian grid is now relatively mature. In 2006 the first Basslink undersea HVDC interconnector came into service: running at 400kV; and rated to transmit up to 500 megawatts (MW) in either direction. At 290 km the undersea cable component was then the second longest of its type in the world.

Given its success the $3.5bn 'Marinus Link Project' is now underway (planned to come on-line in the late 2020's), incorporating an additional 1500 MW high voltage direct current (HVDC) undersea interconnector, in order to exploit Tasmania's excellent wind resources.

Similar technology could be used on other very long interlinks but at present the economics still favour AC links in part because, with AC at both ends, and multiple links, grid synchronisation is better facilitated. Thus the Haywood interlink, between Victoria and South Australia, is 275 kV AC and maintains synchronisation between the states.

The failure of the Hayward link in 2020 provides a good example of the challenges presented by misaligned electricity demand and supply peaks - in that case, due to a very large fall in wind generation.

South Australia separates from NEM, again, as interconnector troubles returnUpdate – As of 8:05pm, the Australian Energy Market Operator has confirmed that South Australia has been re-synchronised with the rest of the National Electricity Market and power flow has been restored via the Heywood terminal. Michael Mazengarb in Renew Economy - 2 March 2020 |

.

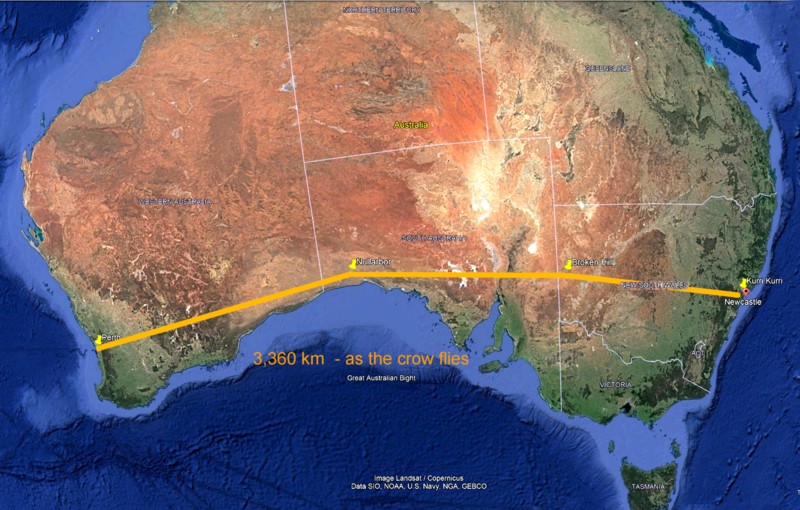

Some blue-sky enthusiasts suggest that a DC grid will form the future electricity transport backbone; for example: to span the 4,000 kilometres from Sydney to Perth.

This would pose significant challenges including crossing two mountain ranges and a lot of desert. Losses would be prohibitive unless the voltage used was very high indeed, in the millions of volts, requiring very high transmission towers or exceptional insulation and cable cooling.

An alternative could be a superconductive interlink.

The electrical conductivity of most metals (and other conductors) changes according to temperature.

Except in some exotic materials, they become more conductive as temperature falls.

Some metals like niobium-titanium or niobium-tin alloys become superconductors at very low temperatures, just above absolute zero. That means that electrical currents are transmitted freely with no resistive losses; and consequently, no electrical heating.

The Large Hadron Collider (LHC) has miles of superconducting magnetic coils. Many magnetic resonance imaging (MRI) machines in hospitals employ similar coils.

To make such a super conducting magnet the wire needs to be bathed in liquid helium. This reduces its temperature to just four degrees above absolute zero. The boiled-off helium gas is then recovered and re-compressed to liquid helium in extremely sophisticated cryogenic apparatus. Not only is this apparatus very expensive but it consumes energy to remove heat leaking into the system.

According to the CERN website - the LHC's cryogenic system employs 120 tonnes of helium to keep the superconductors at 1.9 K (−271 °C, −456 °F). Running the cryogenic system including: circulating the liquid; recompressing the boiled off helium gas; and disposing of the heat continuously consumes 40 MW of electricity.

If this cooling system fails, at any point in the conduction path, the material ceases to super-conduct. The very high currents in use instantaneously vaporise the metal at that point, often causing an explosion and/or very serious equipment damage. This happened catastrophically in one of the first runs of the LHC, shutting it down for nearly a year.

This risk, together with the financial and energy cost of supercooling present generation superconductors, if they were stretched out in hot environments over hundreds or thousands of kilometres, makes them impractical at present for commercial electricity transmission.

But research continues into high temperature superconductors. These already exist in the laboratory but seem to collapse under high magnetic fields; making the present generation useless for high power applications. Their operation involves quantum mechanics and is still somewhat mysterious. This is one area in which a better understanding of quantum mechanics, in part through work at the LHC, might change the future.

Generation

Assuming anthropogenic climate change has reached criticality, principally due to overpopulation, the World needs to urgently reduce our consumption of fossil fuels. See: Climate Change - a Myth? on this website.

At the moment our only significant economic alternatives to fossil fuels, presently required to provide energy when the wind is not blowing and the sun is not shining, are hydroelectricity and nuclear (fission) power. Recent studies show that 'fracking' for gas and even burning wood are potentially worse for the environment than burning coal.

Uranium is presently the principal nuclear fuel but as the very heavy elements, like uranium and gold, are created in comparatively rare neutron star mergers, these elements were also relatively rare in the dust that coalesced to become the Earth, so accessible resources are limited, maybe to a millennium worth of fuel. Fortunately to those recourses we can add thorium that can be 'bred' as a potentially safer nuclear fuel.

So with wind and solar generation meeting up to half the demand, the World could wean itself off burning coal and gas for electricity within a few decades; and still have sufficient energy to reduce dependence on petroleum and sustain a population of ten or eleven billion with more equity in health and material wellbeing, next century.

After uranium and thorium, we have an almost limitless source of energy - nuclear fusion.

The Sun is powered by fusion but on Earth the sun's energy fluctuates too much to gather its energy easily; due to the Earth’s rotation; and the tilt of its axis that gives us summer and winter. It also gives us tides and generates the weather, that gives us wind energy, but all these factors get in the way of the radiant energy reaching our solar panels on a consistent basis.

Some commentators have suggested that solar collectors in orbit would provide a 24/7 energy supply if we could get it down to the surface. We might do this with lasers or microwaves. In either case there would be very significant dangers and environmental considerations to be addressed. Either method would make a very nice James Bond, or even Star Wars, style death ray.

But we have already harnessed this source of energy on Earth energy many hundreds of times. It is the principal source of energy in the hydrogen bomb. Unfortunately, we don't want all that energy at once.

Scientists have recently succeeded in creating controlled fusion on a small scale in the laboratory. But this is far too small and costly to be of commercial use.

Somewhere in between would be good.

At the moment there is no practical commercial reactor in sight; principally because conventional nuclear fission reactors, using uranium (and other unstable heavy elements) are a lot less complex and therefore less costly.

But work continues. A complexity or cost breakthrough in nuclear fusion would solve our energy needs as a central issue facing mankind; particularly if we are also successful in reducing world population to sustainable levels in the future.

The ultimate Science Fiction (or Pons and Fleischmann/ Back to the Future) dream is that particle physics may someday reveal a reversible way to store energy as mass and then recover it as energy when wanted; cheaply with little or no loss. Batteries already do this on an infinitesimal scale but a gram or so of mass is presently out of reach.

This is like the alchemists dream of turning base metals into gold.

It would be far more valuable than that. The entire energy transport network; the grid; gas; and petrochemicals; would become redundant.

You might wonder why I'm bothered with this subject.

The answer is that electricity has always been part of my life; and that of my ancestors almost since it was discovered (see The McKie Family - Untimely Death).

Indeed, it has probably always been part of your life too. It's the revolutionary discovery that has led to the modern world. So it shouldn't it be of interest to everyone?

Joke: How many New Yorkers does it take to change a light bulb? Two: One to call the handyman; and one to mix the cocktails while they wait.

Note: Some content previously here has been moved to The McKie Family - My Inheritance

Appendix

The Australian National Electricity Market

To supply that energy there are many hundreds of increasingly diverse electricity generators supplying the National Electricity Market (NEM). All states except Western Australia and the Northern Territory are connected to the eastern grid and electricity can flow forwards and backwards across state boundaries according to demand and supply.

This pool of suppliers, thus created, forms the National Electricity Market (NEM). This functions as a central dispatch system and is managed by the Australian Energy Market Operator (AEMO).

The NEM is a wholesale market through which generators and retailers trade electricity. There are six participating jurisdictions (five states and the ACT) linked by transmission network inter-connectors.

In the larger States, the energy available from the NEM is derived, predominantly, by burning coal and gas. The exceptions are South Australia and Tasmania that rely more on wind and hydro-electricity respectively.

| Australian electricity generation, by fuel type 2020

(source: Department of Industry, Science and Energy and Resources website) |

||

| TWh | % | |

| Non-renewable fuels | ||

| Black coal | 108.75 | 41% |

| Brown coal | 34.18 | 13% |

| Natural gas | 53.12 | 20% |

| Oil products | 4.51 | 2% |

| Total non-renewable | 200.57 | 76% |

| Renewable fuels | ||

| Bioenergy | 3.41 | 1% |

| Wind | 22.61 | 9% |

| Hydro | 14.81 | 6% |

| Large-scale solar PV | 8.12 | 3% |

| Small-scale solar PV | 15.72 | 6% |

| Geothermal | 0.00 | |

| Total renewable | 64.67 | 24% |

The electricity price in this market place is governed by demand and supply within wide limits.

The Australian Energy Regulator monitors the market to ensure that participants comply with the National Electricity Law and the National Electricity Rules. These rules set a maximum spot price of $15,000 per MWh (From 1 July 2020). The also set a market floor price; presently negative $1,000 per MWh.

The prevailing spot price can be seen on the AEMO website.

For a full explanation of the Australian NEM go here...

Based on the generator’s offers to supply and the prevailing demand, AEMO’s systems determine the generators required to produce electricity based on the principle of meeting the retailers’ demand in the most cost-efficient way. AEMO then dispatches these generators into production.

The dispatch price between the market and generators is struck every five minutes and averaged to the NEM spot price every half hour for each of five generation regions. This price fluctuates very substantially according to season and time of day with additional variability due to sun, wind, or rain and even what’s on TV.

In meeting a particular demand AEMO calls for offers to supply. It then 'stacks' these from lowest to highest; the final and highest price being the last to complete the stack.

This is made more complex by a market intervention known as the mandatory Renewable Energy Target (RET), an Australian Government scheme designed to "reduce emissions of greenhouse gases in the electricity sector and encourage the additional generation of electricity from sustainable and renewable sources". This is achieved by tradable certificates issued by generators employing renewable energy (typically wind and solar). One certificate for each MWh generated and a proportion of these must be acquired by wholesale purchasers of electricity - typically electricity retailers. The price of a Large-scale Generation Certificate (LGC) varies according to supply and demand.

In other words, the LGC' are a mechanism for subsidising renewable electricity generators at the expense of non-renewable generation.

The energy captured by wind and solar power stations is, obviously, free. The electricity cost is entirely due to the capital invested overall; the cost of servicing that capital (interest / opportunity cost); the cost of depreciating the equipment (maintenance; it's removal/remediation after end of life etc); the staff costs related to the venture; and profit.

Because wind and large-scale solar photovoltaic (PV) generators have zero fuel cost, and receive one LGC for each MWh provided, they can have negative effective energy cost and bid at the lowest price. So, if wind or large-scale PV is available, it goes to the bottom of the stack.

The price of fuel to a thermal station determines the lowest price they can bid without losing money.

Less efficient thermal stations, and those burning more expensive fossil fuels, will be at the top of the AEMO stack. These are the first to miss out when demand is low. But base-load stations need to keep spinning even when there is no load, so they need to bid low to come into the stack, even at the risk of a price at which they will lose money.

The effect of LGC's is to suppress the market price and make some thermal stations unprofitable, even though they are still essential to meet demand at peak times.

At the same time, the consumer is paying more for electricity, than would otherwise be the case, as a result of the cost to retailers of the LGC’s. Some retailers invite consumers to pay more for a 'green electricity' option.

This may well be a good thing for wind and large-scale PV power; but not everyone in the industry is delighted. Some suggest that this is removing the market incentive to invest in new base-load capacity.

But the market distortions introduced by the Renewable Energy Target have been declining for some time. LGC the price (the effective subsidy to large-scale wind and solar) remained at around $80 a MWh until 2018 the price has since fallen steadily to around $35 in 2020 and is expected to halve again, due to new investment in renewables exceeding the generation levels needed to meet the present target.

While government incentives to move to renewable energy vary, most other wholesale electricity markets around the world, for example in the EU, operate in a similar manner.